TCM-A/TCM-B RANGATIRA ARATOHU ROD CHINA ALUMINIUM ALLOY TUBE

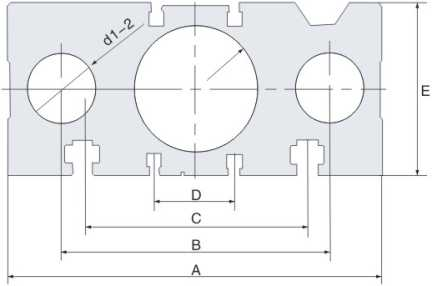

TCM-A (φ12-80) Rangatū Tube Cylinder

| No | d | d1-2 | A | B | C | D | E |

| 1 | φ12 | φ10 | 58 | 41 | 37 | 9 | 26 |

| 2 | φ16 | φ12.5 | 64 | 46 | 38 | 10.5 | 30 |

| 3 | φ20 | φ14.5 | 83 | 54 | 44 | 12.5 | 36 |

| 4 | φ25 | φ18 | 93 | 64 | 50 | 15 | 42 |

| 5 | φ32 | φ22.5 | 112 | 78 | 63 | 19.5 | 48 |

| 6 | φ40 | φ22.5 | 120 | 86 | 72 | 25 | 54 |

| 7 | φ50 | φ27.5 | 148 | 110 | 92 | 33 | 64 |

| 8 | φ63 | φ27.5 | 162 | 124 | 110 | 34 | 78 |

| g | φ80 | φ34 | 202 | 156 | 140 | 48 | 91.5 |

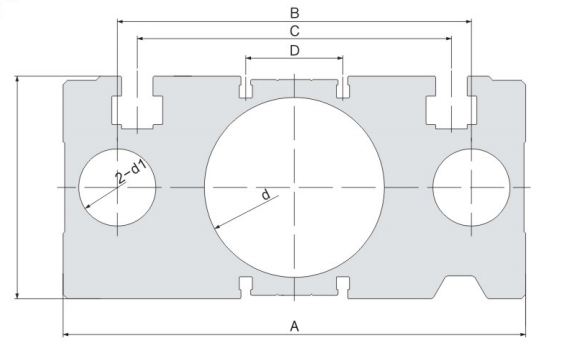

TCM-B (φ12-63) Rangatū Tube Cylinder

| NO | d | 2-d1 | A | B | C | D | E |

| 1 | φ12 | φ10 | 58 | 41 | 37 | 9 | 26 |

| 2 | φ16 | φ13 | 64 | 46 | 38 | 10.5 | 30 |

| 3 | φ20 | φ17 | 83 | 54 | 44 | 12.5 | 36 |

| 4 | φ25 | φ18 | 93 | 64 | 50 | 15 | 42 |

| 5 | φ32 | φ22.5 | 112 | 78 | 63 | 19.5 | 48 |

| 6 | φ40 | φ22.5 | 120 | 86 | 72 | 25 | 54 |

| 7 | φ50 | φ27 | 148 | 110 | 92 | 33 | 64 |

| 8 | φ63 | φ27 | 162 | 124 | 110 | 34 | 78 |

Rauemi o te konumohe Alloy Profile Aluminium ngongo pneumatic cylinder: konumohe koranu 6063 T5

Ko te roa o ta maatau paerewa he 2000mm, mena ka hiahia etahi atu roa, tena koa whakamarama mai.

Mata anodized: ngongo roto-15±5μm ngongo waho-10±5μm

Ka rite ki te hoahoa FESTO, SMC, Airtac, Chelic etc.

E ai ki te paerewa ISO 6430 ISO6431 VDMA 24562 ISO15552 etc.

Whakamahia mo te rango paerewa, rango kiato, rango paku, rango rua Roda, rango Kiriata, rango Ripanga Kiriata, Gripper aha hoki etahi rango motuhake.

Hanganga matū:

| Hanganga matū | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti |

| 0.81 | 0.41 | 0.23 | <0.08 | <0.08 | <0.04 | <0.02 | <0.05 |

Whakatakotoranga:

| Te Kaha Ririhi (N/mm2) | Kaha Tuku (N/mm2) | Maamaa (%) | Maamaa Mata | Tikanga Diamita o Roto | Roto Riro | Te tika | Hapa Matotoru |

| Sb 157 | S 0.2 108 | S8 | HV 300 | H9-H11 | <0.6 | 1/1000 | ± 1% |

Tolerance o Aluminium Alloy Tube:

| TORLERANCE OF ALUMINIUM ALLOY TUBE | ||||||

| Rahi Poka | TORLERANCE | |||||

| mm | H9(mm) | H10(mm) | H11(mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

FAQ:

Q1: He aha te tauira TCM?

A: āhuatanga hua

1. Ka whakatinanahia te paerewa JIS

2. E rua nga kaiarahi o te rino kawe motuhake me te raina raina, te arataki kawe parahi ranei e whakamahia ana hei aukati i te hurihuri.Ka taea e ratou te kawe i te taipana teitei me te kawenga radial.

3. Ko te waahanga taraiwa me te waeine kaiarahi kei roto i te putea kotahi kaore he taputapu taapiri e hiahiatia ana me te iti o te waahi e hiahiatia ana Ko te whakauru hau he mea whiriwhiri, he pai ki te whakauru.

4. Ko te taha o raro, te taha o muri me te pereti whakatika o te tinana matua e rua nga tuunga tuunga tika (Tirohia te Orifice PA me te orifice i te tohu XX), ka taea te whakauru i te whakatakotoranga me te tino tika mo te ahuatanga motuhake.

5. Kōwhiringa o te whakapuru whakapuru ki te whakarato 4 mokamoka whakapuru.

6. Ko te hoahoa motuhake o te tinana matua e whakarato ana i te maha-maunga;

Q2: Mena ka hokona e matou te TCM, ka taea pea me te anodizing mo te Aluminium Air Cylinder Tubes?

A: Ko tenei Pneumatic Cylinder kaore i te tūtohu kia oxidized, na te mea me tapahi te kaihoko i a ia ano, ka tukatuka ka mahi i te maimoatanga hāora i muri i te hoko.

Q3: He aha te roa ki te tono matou i te Pneumatic Cylinder Tube Pipe?

A: 2 mita te roa.

Q4: Wpōtaeko te wa tukumō Profile Aluminium mo te Air Cylinder?

A: ☆ Mena kua whakaritea nga ngongo, me 50-60 nga ra mahi, engari ki te mea mo nga ngongo paerewa, ko te wa tuku he 15-20 ra mahi.